Ceramic and metal injection molding case application part application material weight g tolerance mm special characteristic technical data sleeve dental implant al 2 0 3 99 99 0 4 0 02 bio compatible.

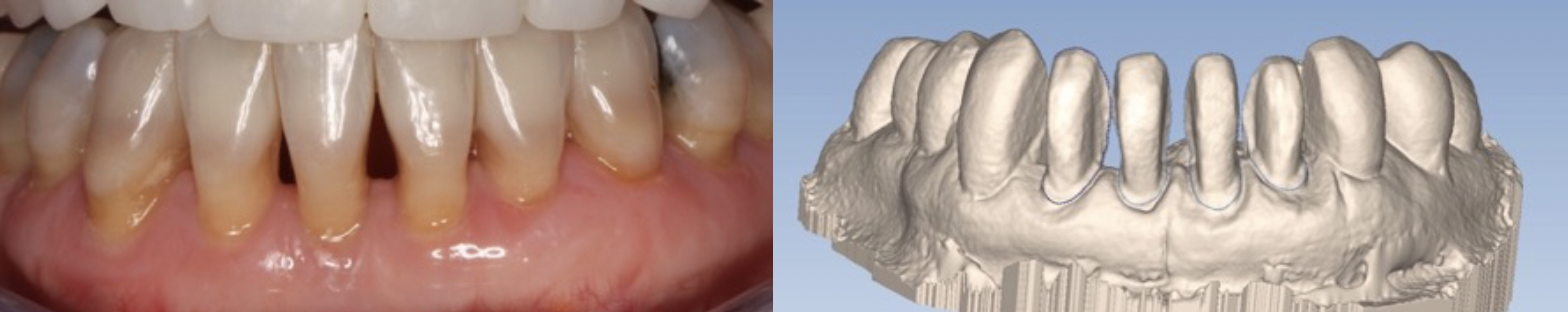

Ceramic tooth injection mold.

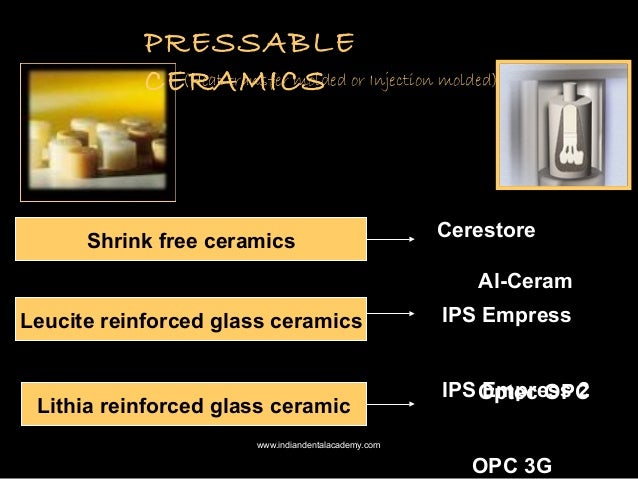

Ceramic powders are added to plastic as filler.

General capabilities include the following.

Akron porcelain plastics company has the advanced technology to produce ceramic injection molding cim components.

Parts weighing from 0 1 g to 150 g.

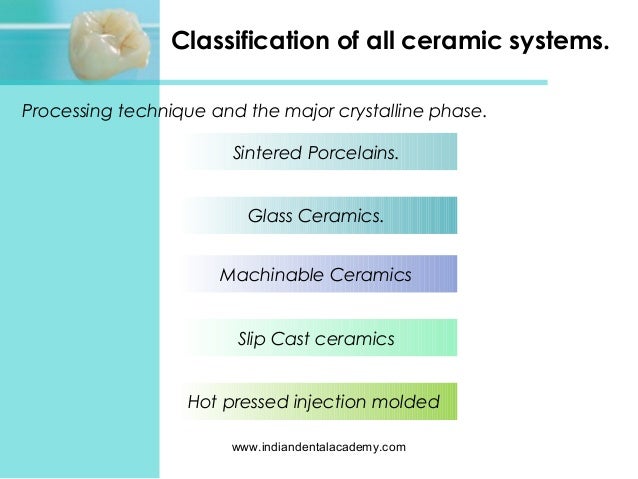

Ceramic injection molding is ideal for high volume production of complex tight tolerance components.

Akron porcelain plastics company offers custom molding for dry process wet process sand casting investment casting and injection molding.

The cim process gives production engineers and product designers more versatility in the use of ceramics as an alternative material with higher productivity lower manufacturing cost s and improved product performance.

Ceramic injection molding is most advantageous when a project requires a complex shape with tight tolerances to 0 5 consistent quality and high volumes.

Binder removal is the most crucial step.

For injection molding of ceramic parts the die must be made of harder and wear resistant metal alloy.

Additional products cerama nut wire connectors knobs and housings pipe thread bushings spools strainer cores tubes water filtration.

Finer ceramic powders could be injection molded by using low molecular weight binder systems but these pose particle packing problems.

They offer many insulator products.

Evaporation or distillation ii.

Tolerances down to 1 2 of dimension or 0 0005.

Enjoy the videos and music you love upload original content and share it all with friends family and the world on youtube.

Electrical tubes pin type guy strain suspension cable rack and line post.

The shaped tool is cooler than the injection molding mix.

Using an injection mold machine these parts can meet high technical standards and aesthetic requirements.

Cim is suitable for high volume production of complex ultra precision ceramic parts of various sizes.

Mold cavitation from 1 to 10 parts.

Our ceramic molding capabilities include injection molding and other manufacturing processes which allow us to provide finished parts to our customers exact specifications.

With consistent mixing and forming cim offers superior performance characteristics of ceramics along with the ability to attain extremely tight and uniform tolerances 0 005.