However these pellets manufactured by pressing and sintering ceramic uranium dioxide powder are generally of high density typically greater than 95 theoretical density or 10 40 g cm3 whereas.

Ceramic uranium pellets.

The zircaloy tubes are about 1 cm in diameter and the fuel cladding gap is filled with helium gas to improve the conduction of heat from the fuel to the cladding.

Uranium dioxide uo2 uranium dioxide is a ceramic refractory uranium compound in many cases used as a nuclear fuel.

A reactor core is typically made up of a couple hundred assemblies depending on power level.

Uranium dioxide is a black semiconducting solid with very low thermal conductivity.

The fabrication of ceramic pellets is also described and discussed.

Details are given about oxide microsphere synthesis and particularly about loading operation and heat treatments.

For this latter purpose the uranium dioxide pellets are sintered to a density.

Uranium silicide u 3 si 2 fuels for research reactors are being developed at inl also in the second phase the uranium silicide fuel pellets would be in silicon carbide ceramic matrix composite cladding with a melting point of 2800 c and these test assemblies could be loaded into a reactor by 2022.

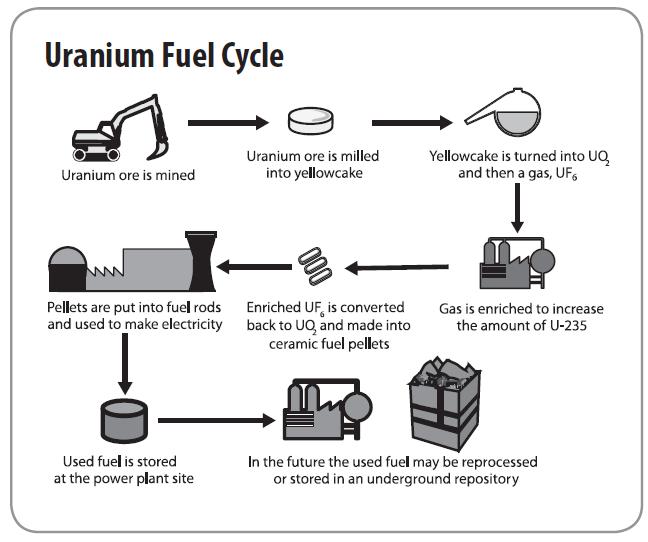

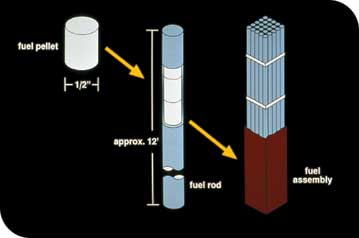

The pellets are subsequently inserted into thin tubes known as fuel rods which are then grouped together to form fuel assemblies.

The uranium is processed into small ceramic pellets and stacked together into sealed metal tubes called fuel rods.

Typically more than 200 of these rods are bundled together to form a fuel assembly.

The enriched uranium is transported to a fuel fabrication plant where it is converted to uranium dioxide powder.

This powder is then pressed to form small fuel pellets and heated to make a hard ceramic material.

Uranium dioxide uo2 uranium dioxide is a ceramic refractory uranium compound in many cases used as a nuclear fuel.

Uranium dioxide is a black semiconducting solid with very low thermal conductivity.

Most of lwrs use the uranium fuel which is in the form of uranium dioxide chemically uo2.

This study concerns the fabrication of uranium oxide pellets using the powder free process called calcined resin microsphere pelletization crmp.

Uranium ceramic pellets faster longer trips to space may be on the horizon thanks to new nuclear engine design welcome to thomas insights every day we publish the latest news and analysis to keep our readers up to date on what s happening in industry.

Most of lwrs use the uranium fuel which is in the form of uranium dioxide chemically uo2.

The initial encore fuel comprises high density uranium silicide fuel pellets inside zirconium cladding with a thin coating of chromium making it more robust chemically.